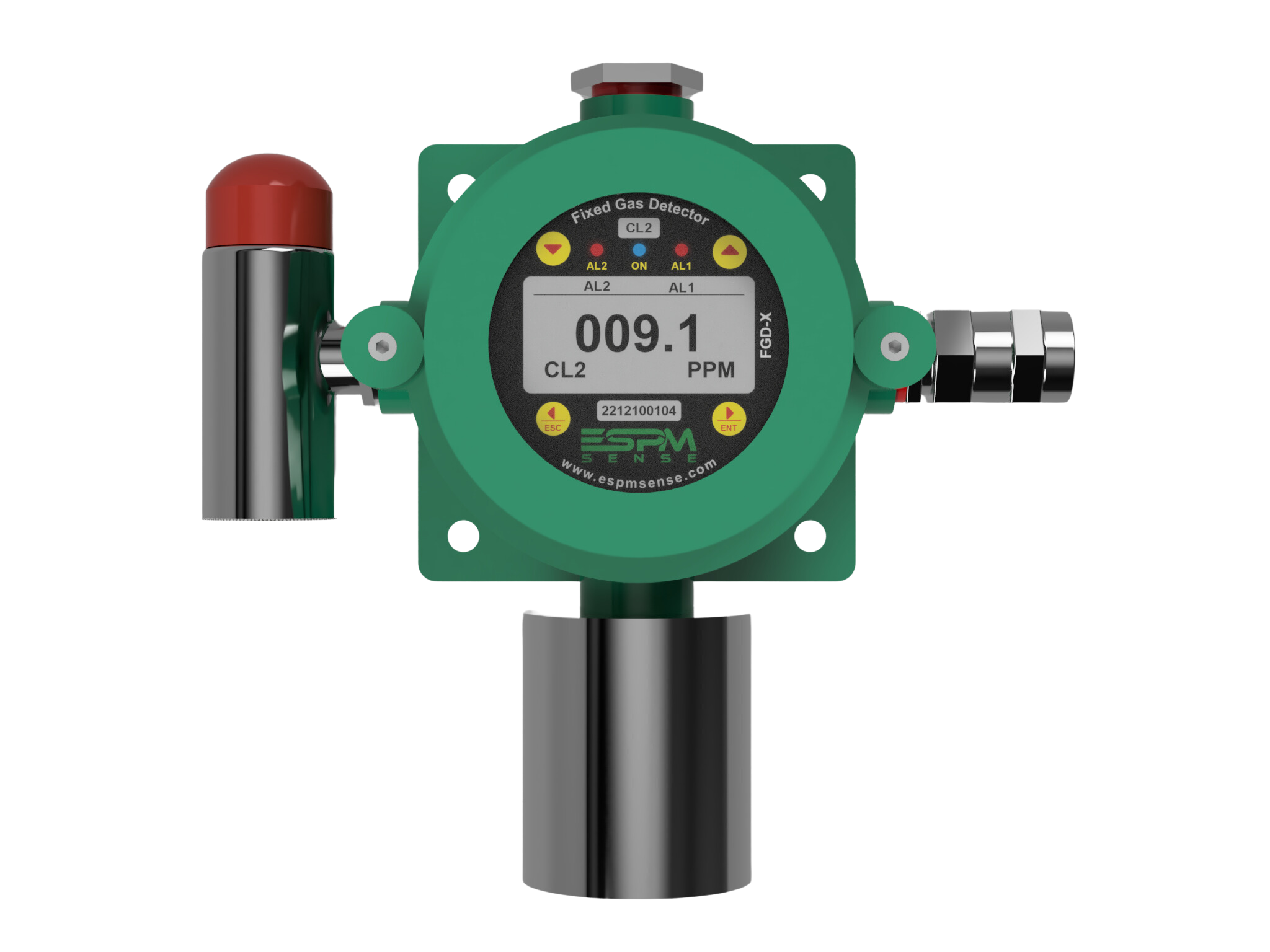

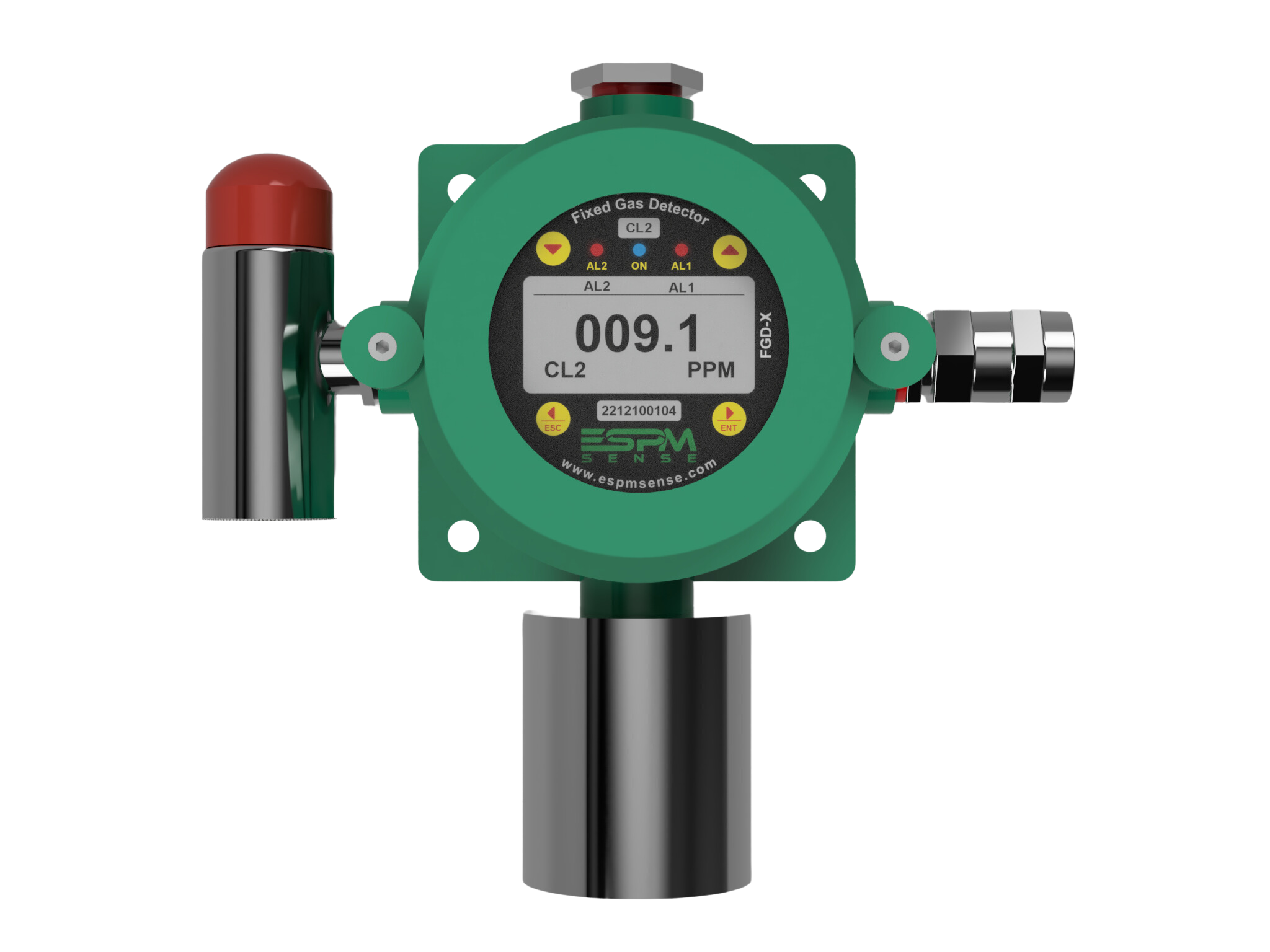

FGD-X

Fixed point Gas Leak Detector

Microcontroller-based Gas leak detector for detecting Flammable Gas Hazards, Toxic Gas Hazards and Asphyxiant (Oxygen Deficiency) Hazards at fixed points in industry.

Process Gas Analysis refers to the continuous monitoring and measurement of gases involved in industrial processes. This is done to ensure optimal process control, energy efficiency, product quality, and regulatory compliance. In industries such as chemical manufacturing, oil and gas, power generation, and food processing, analyzing process gases is critical for maintaining operational safety and efficiency. Process gas analyzers help industries monitor gases like oxygen, carbon dioxide, nitrogen, and various hydrocarbons in real time, providing valuable data to optimize production processes and ensure environmental compliance

*Terms and Conditions Applied:

*Terms and Conditions Applied:

Key Benefits

6 key benefits of using Process Gas Analysis systems in your plant

Products we provide

To detect Process Gas

Microcontroller-based Gas leak detector for detecting Flammable Gas Hazards, Toxic Gas Hazards and Asphyxiant (Oxygen Deficiency) Hazards at fixed points in industry.

Portable equipment to detect microcontroller-based Gas leak detector for detecting Flammable Gas Hazards, Toxic Gas Hazards and Asphyxiant (Oxygen Deficiency) Hazards.

Portable equipment to detect microcontroller-based Gas leak detector for detecting Flammable Gas Hazards, Toxic Gas Hazards and Asphyxiant (Oxygen Deficiency) Hazards.

Use Cases

10+ most used applications of Process Gas Analysis